The Volkswagen auto parts industry is embracing new opportunities for positive development

With the profound transformation of the global automotive industry, Volkswagen, as an industry giant, is leading its supporting industrial chain into a brand-new stage of development. In recent years, the Volkswagen auto parts industry has shown many positive trends in areas such as electrification, digitalization, green manufacturing, and local cooperation, bringing broad market prospects and innovation opportunities to upstream and downstream enterprises.

The electrification transformation drives the upgrading of components

Volkswagen Group is fully promoting its electric vehicle strategy, and the ID. series models have achieved remarkable results in multiple global markets. This transformation has driven a brand-new demand for electric accessories, such as electric drive systems, battery management components, heat pump air conditioning systems, etc. The introduction of a large number of new technologies and materials has enabled traditional accessory enterprises to start transforming towards high value-added products, enhancing the technological level and profit margin of the entire industrial chain.

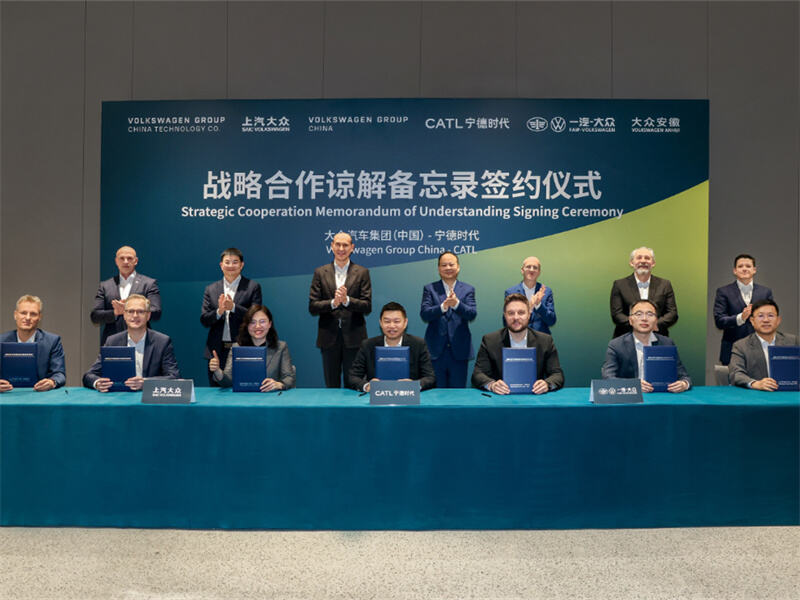

Localized cooperation enhances supply chain resilience

In the Chinese market, Volkswagen has been continuously intensifying its localization strategy and has established in-depth cooperative relationships with many parts enterprises, including CATL, Huayu Automotive, and Bosch China. This strategy not only shortens the delivery cycle, but also reduces costs and enhances flexibility in responding to market changes. Local accessory enterprises have thus achieved rapid growth and enhanced their global competitiveness.

The after-sales market continues to recover

The number of cars in China is constantly rising, especially with the extensive coverage of Volkswagen brands in the mid-to-high-end market, which has led to the continuous expansion of its after-sales parts market. From regular maintenance to customized modifications, the demand for original factory and high-quality aftermarket parts continues to grow. The improvement of accessory suppliers in aspects such as quality guarantee services, channel construction, and logistics capabilities is also accelerating the standardization and branding process of the industry.

Intelligent manufacturing promotes the dual improvement of quality and efficiency

By leveraging Industry 4.0 and the intelligent manufacturing system, Volkswagen and its component partners have widely introduced AI algorithms, Internet of Things devices and intelligent detection systems to achieve comprehensive digitalization from production to quality control. The construction of smart factories not only enhances the consistency and reliability of components but also accelerates the speed of product updates and iterations, meeting the market's demand for efficient supply.

Green transformation drives innovation in sustainable materials

Volkswagen Group is strengthening its sustainable development strategy globally and promoting the transformation of its components towards environmental protection and low carbon. The application of green accessories, including recyclable materials, bio-based plastics, and low-carbon steel materials, is gradually expanding. This trend is driving accessory enterprises to constantly innovate in material research and development and production processes, seizing the development opportunities of the "green supply chain".

Conclusion

The Volkswagen auto parts industry is standing at the intersection of technological transformation and market restructuring. The combination of positive factors such as electrification, digitalization, green manufacturing, and local cooperation has brought new growth engines to accessory enterprises. Facing this period of opportunity, only by accelerating transformation and upgrading and strengthening innovation capabilities can related enterprises stand out in future competition.